ABD’de Prof. Dr. Nejat Olgaç ve başında bulunduğu araştırmacıların, kök hücreler üzerinde araştırmalara hız getirecek yenibir yöntem geliştirdi.

Prof. Dr. Nejat Olgaç ( Nejat Olgac ) Kimdir?

Connecticut Üniversitesi Makine Mühendisliği Bölümü Öğretim Üyesi Nejat Olgaç, yaptığı açıklamada, ”Buluşumuz sadece kök hücre konusunda değil, aynı zamanda tüp bebek ve klonlama sahalarında da çok etkili ve pratik klinik uygulamaları beraberinde getirecek” dedi.

Olgaç’ın verdiği bilgiye göre, rotasyonel-titreşimli hücre delici ”Ros-Drill” olarak isimlendirilen bu buluş sayesinde araştırmacılar, fareler üzerinde yapılan biyolojik testlerde oldukça ”hızlandırılmış, yüksek hassasiyette ve otomatik duruma getirilmiş tüpte” yavru yetiştirme ve klonlama sonuçları gözlemlediler.

”Bu buluş kök hücre çalışmalarında çok kritik bir açığı kapatmakta” diyen Olgaç, yeni teknolojinin laboratuar çalışmalarını son derecede hızlandıracağını bildirdi.

Olgaç, çalışmalarının teknoloji ağırlıklı özetini geçen ay ”Journal of Biomedical Microdevices” adlı bilim dergisinde yayınladığını söyledi.

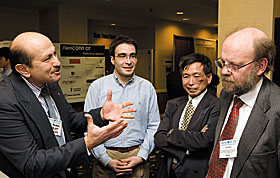

Olgaç, buluşunu bu yıl mart ayında Connecticut’ta düzenlenen uluslararası kök hücre konferansında da (StemCONN07) tanıttığını ve aralarında dünyada ilk kez koyun klonlaması yapan Prof. Dr. Ian Wilmut’un dabulunduğu araştırmacıların yeni yöntemin son derece değerli bir katkı olduğunu ifade ettiklerini dile getirdi.

Konuyla ilgili daha fazla bilgiye Connecticut Üniversitesi’nin internet sitesi http://advance.uconn.edu/2007/070402/07040201.htm ) adresinden ulaşılabilir.

———————————————————

Team creates precision device for use in stem cell research

by Michael Kirk – April 2, 2007

During an international conference on stem cell research in Hartford last week, mechanical engineering professor Nejat Olgac and a team of UConn researchers presented a significant engineering breakthrough in laboratory equipment that has the potential to sharply accelerate the pace of stem cell research.

The new technology, an automated precision microscopic piercing device developed by researchers from the University’s Advanced Laboratory for Automation, Robotics, and Manufacturing, and the Biotechnology Center Transgenic Animal Facility, dramatically improves the nuclear transfer process used in cloning.

The preliminary biological tests performed at the Biotechnology Center for Transgenic Animals Facility have shown that it is easier to use, more accurate, and more effective than current laboratory methods.

It also has the potential for automation, which could substantially reduce the training period for those who use it from about two years to a few weeks and minimize the possibility of human error.

A critical step in the cloning process involves using a tiny glass “pipette” – similar to a hollow needle smaller than a human hair – to pierce an egg or cell to remove the cell’s nuclear material and replace it with donor cell nucleus – a process referred to as nuclear transfer.

Currently, using a high-powered microscope and precision controls, the pipette is manually placed against the outer wall of the target cell. It is then axially forced through, puncturing the cell wall.

This method often causes irreparable damage to the cell, as the tip of the pipette tends to randomly vibrate during the process, lacerating the cell membrane.

The efficiency of nuclear transfer, which is measured after the embryo is placed in the uterus, is quite low (about 1 percent to two percent).

The new technology is expected to bring considerable improvement, especially at the donor cell injection stage.

In state-of-the-art systems today, designers attempt to minimize cell damage by the use of liquid mercury, the high density of which helps dampen the undesired vibration of the pipette.

This approach is broadly used today, despite the problem of toxicity, although some institutions do not allow it. The new technology developed at UConn eliminates the need for mercury.

Olgac’s system, rather than puncture the cell wall, controls rotational vibration of the pipette, thereby creating a drill effect to bore through the cell wall.

This sharply reduces lateral vibration, eliminating the need for mercury, and causes minimal damage to the cell wall membrane.

The glass pipette is attached to a pipette holder, which is connected to the motion-generating motor through a flexible coupling.

The micro-motor is computer-controlled, for rotational oscillations that are precise both in amplitude and frequency.

The pipette itself is designed with a beveled tip, to optimize the cutting action as it is inserted into the cell membrane.

The new method can be used for any elastic structure, giving it potential for use in other medical fields.

From left, Professor Nejat Olgac and graduate student Ali Ergenc explain a precision device they developed for use in stem cell research to Professor Jerry Yang and Ian Wilmut from the University of Edinburgh, during the StemCONN07 conference last week. Wilmut is known for cloning “Dolly” the sheep.